HOW TO RECOGNIZE LENPUR

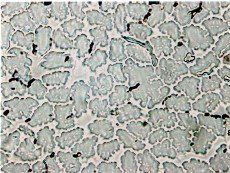

Reactive Test - Iodo-sulphuric reactive test with polarised light.

Lenpur spinning

In order to obtaine a turely homogenous fibre blend, good carding conditions must be maintained during processing as Lenpur® fibers have different cross-sections (0.7 dtx and 1.9 dtx). Machine settings (and twisting delta) must be similar to those used for medium-staple length combed cotton. We recommend a maximum spinning speed of 13,000 rpm. Count range: Ne 6 - Ne 70.

Self-mercerising and dyeing properties

Lenpur fibers are self-mercerizing ( untreated Lenpur with reactive dye ). In all alkaline environments, the fibers swell significantly, increasing shine and softness. This unique self-mercerizing property provides materials with superior dye affinity and excellent luster. Thanks to this property, fabrics made from Lenpur yarns gain extra softness from what is already a soft surface. The cold and warm wash resistance of this fiber is better than that of common artificial cellulose fibres. Its excellent dye affinity reduces streaking to a minimum. Lenpur has excellent dyeability with all cellulosic dyes. Lenpur can be dyed by itself or in blends with other fibres, as a fibre, yarn or fabric, using any any conventional dyeing machine. Compared to artificial fibres dyed under the same conditions, Lenpur has a 10 to 20% higher colour yield when dyed with direct and reactive dyes.